Middle Atlantic Products UP1 Middle Atlantic Products UP1 rack accessory Cable management panel

Can be used for lacing large cable bundles or mounting devices

Middle Atlantic Products UTR1-RP12 Middle Atlantic Products UTR1-RP12 rack accessory Rack shelf

Designed to mount smaller components, wireless units and other non-rackmount equipment. Includes hook-and-loop strips for component mounting. • Features an enhanced ventilation pattern • Constructed from 16-gauge steel • Finished in a durable black powder coat

Middle Atlantic Products VBK-BGR-SA Middle Atlantic Products VBK-BGR-SA rack accessory Vent blocker

Vent blockers are used to prevent the recirculation of hot air between top-mount fans and nearby vent openings. Vent blockers should be placed over the enclosure’s vents located on the upper front of the enclosure, upper sides, and upper rear door (depending on enclosure). This will ensure that heated enclosure air will be forced out through the top-mounted exhaust fans instead of re-circulating, keeping equipment cool.

Middle Atlantic Products VBK-D17 Middle Atlantic Products VBK-D17 rack accessory Vent blocker

Vent blockers are used to prevent the recirculation of hot air between top-mount fans and nearby vent openings. Vent blockers should be placed over the enclosure’s vents located on the upper front of the enclosure, upper sides, and upper rear door (depending on enclosure). This will ensure that heated enclosure air will be forced out through the top-mounted exhaust fans instead of re-circulating, keeping equipment cool.

Middle Atlantic Products VBK-S32 Middle Atlantic Products VBK-S32 rack accessory Vent blocker

Vent blockers are used to prevent the recirculation of hot air between top-mount fans and nearby vent openings. Vent blockers should be placed over the enclosure’s vents located on the upper front of the enclosure, upper sides, and upper rear door (depending on enclosure). This will ensure that heated enclosure air will be forced out through the top-mounted exhaust fans instead of re-circulating, keeping equipment cool.

Middle Atlantic Products VBK-S42 Middle Atlantic Products VBK-S42 rack accessory Vent blocker

Vent blockers are used to prevent the recirculation of hot air between top-mount fans and nearby vent openings. Vent blockers should be placed over the enclosure’s vents located on the upper front of the enclosure, upper sides, and upper rear door (depending on enclosure). This will ensure that heated enclosure air will be forced out through the top-mounted exhaust fans instead of re-circulating, keeping equipment cool.

Middle Atlantic Products VLBX-5.5 Middle Atlantic Products VLBX-5.5 rack cabinet

17 1/4' D X 5 1/2' HOptimized for thermal management of DVRs and other digital equipmentExtensive cable management tie points, EKOs and cable pass-throughsInterlocking top for added security; top removes easily for servicingStandard keylocked vented hinging front doorIncludes cooling fan and washable filterOptional proportional speed thermostatic fan control

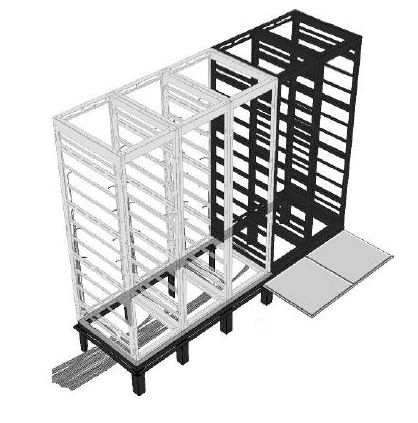

Middle Atlantic Products VMRK-54LRD Middle Atlantic Products VMRK-54LRD rack cabinet 54U

31 2/5' D X 100-5/8” H Without Rear Door This taller version of our broadcast standard 22” wide rack has extra height for taller spaces – delivering a full 54 rackspaces in the same floor space as a standard rack. Built-in horizontal lacing bars enable quick tie-and-slide lacing of video cable bundles. Specify a VMRK to maximize capacity, and where seismic certification and open or removable sides are required or preferred. Fully welded construction for strength 54 spaces of racking height Racks gang together when fully loaded Multiple lacing points and slotted rail brackets for cable management flexibility Standard front and rear adjustable 10-32 threaded “L-Rail” with numbered spaces

Middle Atlantic Products VRK-44-42HLRD Middle Atlantic Products VRK-44-42HLRD rack cabinet 44U

42' D X 83 1/8” H Without Rear DoorWe designed the broadcast standard 22” wide VRK specifically for mounting video and AV equipment. Built-in horizontal lacing bars are ideal for quick tie-and-slide lacing of video cable bundles. Choose a VRK for a strong, narrow enclosure with seismic certification and open or removable sides.Fully welded construction for strengthBuilt-in horizontal lacing bars on 7” centers for quick “tie-and-slide” lacingRacks gang together when fully loadedStandard front and rear adjustable 10-32 threaded rackrail with numbered spaces

Get a Quote

Item(s) added to cart

Netgear GS105E-200NAS ProSafe Plus Switch, 5-Port Gigabit Ethernet - 5 Ports - 2 Layer Supported - Wall Mountable - Lifetime Limited Warranty-None Listed Compliance

MFR: Netgear, Inc

Qty: 1

Part #: GS105NA